FEP – Fluorinated Ethylene Propylene Applications

Fluorinated Ethylene Propylene (abbreviated FEP) was originally invented by DuPont, and sold under their PTFE brandname. It is a thermoplastic resin that can be melt processed using conventional techniques. FEP films are available with one or both sides treated for bonding. FEP typically melts between 535 – 550 Degrees F

Benefits & Liabilities of FEP

Benefits

- Wide thermal operating range from -190C to 205C

- Excellent chemical resistance

- Excellent Corrosion Resistance

- Low coefficient of friction

- Excellent resistance to UV and X-ray radiation

- Highly Transparent

- Excellent electrical insulating properties

- Dimensional stability

- Non-Stick

- Low co-efficient of friction

- Flame Retardant

Liabilities

- High Cost

- Low abrasion resisitance

- High Density

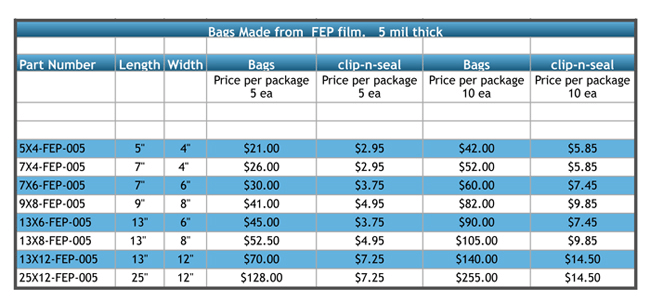

Ingeniven designs and fabricates custom orders using FEP in addition to standard orders of FEP Bags

High Performance Film Custom Manufacturing